After applying for a fund from the Bio Bío Regional Government, the company Innocon, located in Coronel, was awarded an amount to develop the project for innovation in aquaculture for sustainable and efficient production.

The salmon farming industry has faced significant challenges in the development of foods with high lipid content, seeking to enhance the energy supplied and balance amino acids to optimize protein synthesis. Although progress has been made by incorporating 37% fat in 12 mm extrudates, a critical complication arises: fat loss during storage. Current solutions, such as coatings based on saturated fatty acid triglycerides, have contributed to environmental problems while presenting limitations in fat digestibility.

In response to this problem, a revolutionary solution is presented that will transform the aquaculture industry thanks to the contribution of the Bio Bío Regional Government through the Innovation Fund for Regional Competitiveness (FIC-R) through which this initiative could be successfully developed.

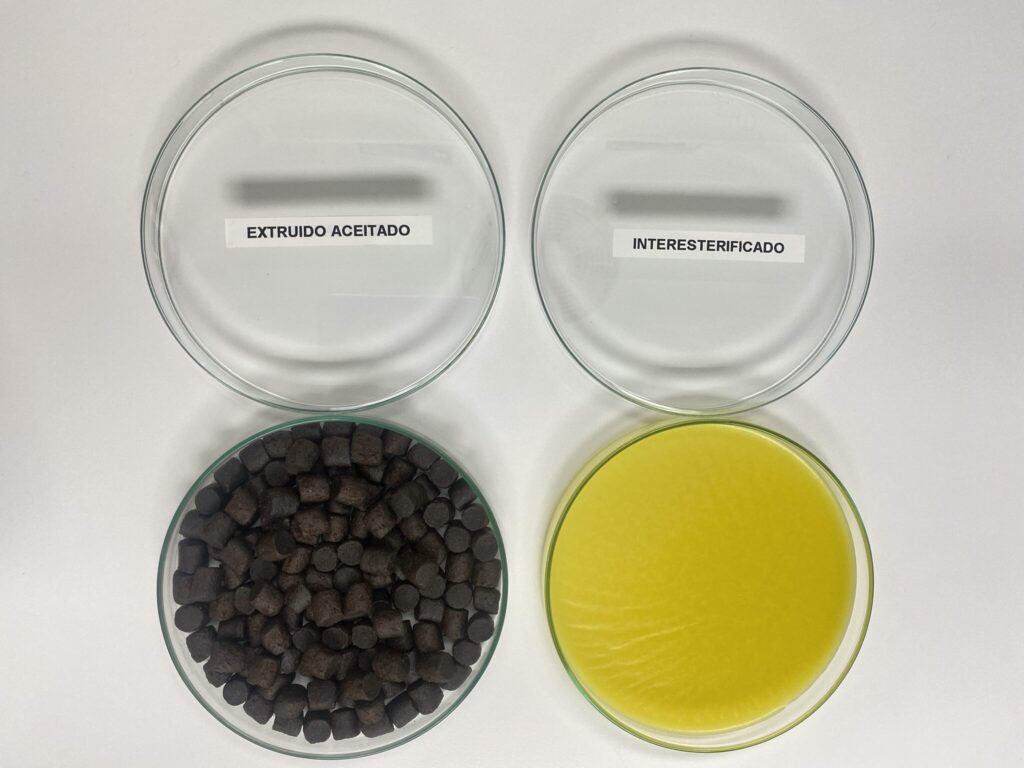

This solution is developed through an interesterification process where the resulting oily product offers ideal rheological characteristics to retain fats in aquaculture feeds. This innovative product is not only completely digestible by fish but is also nutritionally active and environmentally friendly.

The product, obtained from vegetable and animal oils, presents structured triglycerides that include saturated, monounsaturated, and polyunsaturated fatty acids. Its high viscosity at temperatures below 40°C prevents unwanted fat loss during storage, providing an effective solution to the current challenge. Furthermore, its greater digestibility in the salmon system contributes to a greater contribution of metabolizable energy.

Product Technical Characteristics

The interesterified product meets rigorous physicochemical standards, ensuring its quality and effectiveness. With a melting range of 40-43°C, density of 0.80-0.92 g/mL, and shelf life of 3 years, this product is positioned as a reliable and durable option.

In fat retention tests, comparable efficacy was observed between the interesterified product and traditional covering fat. Furthermore, digestibility analyzes showed that the interesterified product surpasses the cover fat, with a 30% greater digestibility. Designed for application during the oiling stage, the product offers a flexible dosage between 0.5% and 1.5%.

With this innovation, the aquaculture industry takes a firm step towards a more sustainable and efficient future, addressing crucial challenges and promoting responsible practices in aquafeed production.

The product has the following physicochemical characteristics:

| Parámetro | Unidad | Resultado |

| Ácidos grasos libres | % | <5,0 |

| Humedad y materia volátil | % | <1,0 |

| Impurezas insolubles | % | <1,0 |

| Índice de peróxido | meqO2/Kg | <5,0 |

| Densidad a 20°C | g/mL | 0,80-0,92 |

| Rango de fusión | °C | 40-43 |

| Constante de aumento de viscosidad | cP/°C | 6,93 x 105 |

| Ácidos grasos saturados | % FAMe | <60% |

| Ácidos grasos monoinsaturados | %FAMe | >14% |

| Ácidos grasos poliinsaturados | %FAMe | >22% |

| Vida Útil | Años | 3 |

| Viscosidad a 40°C | (x106) cP | 1,5 – 1,9 |

| Viscosidad a 45°C | (x106) cP | 0,025-0,038 |

| Viscosidad a 50°C | (x106) cP | 0,005-0,01 |

Fat retention in aquaculture extrudate is similar when using the interesterified product or the covering fat (currently used product).

| Grasa retenida (Día 14) | ||

| T° | 0,7% Cobertura | 0,7% Producto |

| 20°C | 97,69 | 95,15 |

| 30°C | 96,25 | 95,06 |

| 40°C | 95,36 | 93,84 |

In the digestibility tests, it was observed that the interesterified product has a greater digestibility than the covering fat, since in the pellet obtained in the In Vitro digestibility tests, the pellet with 0.7% of interesterified product has 3.18%. of fat, while the control pellet (covering fat) has 4.5%. The digestibility of the interesterified product is 30% greater than that of the covering fat.

The interesterified product is designed to be applied to salmon feed during the oiling stage in a dosage between 0.5% to 1.5%.